- Why Verature?Find out why Verature is the best system for continuous contractor compliance.

- Arrive, Work & Stay Safe

- Removes Paper & Spreadsheets

- Tracks Key Contractors

- Instant 360 Visibility

- Contractor Management Dashboards

- Why Contractor Management Software

- Our Customer Reviews

- Pricing

We don’t hide behind fancy sales teams before we tell you, our prices.- Clients

See who we are working with and what they have to say about Verature.- Resources

Check out our blog, useful guides, whitepapers and product videos.- Prequalification and Induction Guide

- Contractor Compliance Guide

- Mini-Audit your Permit to Work System

- Health and Safety Audit Checklist

- Resource Library

- Blog

Book a demo

What Should Your Permit to Work System Include?

A Permit to Work System is a standardised procedure for ensuring the safe execution of work in a specified region or on specific equipment. It is often employed in industries such as construction, oil and gas, and manufacturing where there is a danger of harm or equipment damage as a result of the activity being done.

A work permit authorises named personnel to undertake a certain job in a specific place or location within a specified time frame. It verifies that all precautions and mandatory checks were carried out before, during, and after the job was done. Work permits are typically associated with high-risk or hazardous tasks such as working at heights, working in tight spaces, working with explosives, hot works, electrical work, excavation jobs, and so on. A general permit to work is sometimes issued to analyse and determine whether additional permits are required.

What Should be Included in a Permit to Work?

Here are just some of the many facto that should be included in a permit to work:

- A permit reference number; you must be able to identify and retrieve a permit for audit purposes.

- The date and time of issue; permits must be performed in real time so that any hazards and work assessments are dynamic and current.

- How long the permit is necessary; this may or may not be enough time to complete the task, and the laws governing how long a permit can be issued differ by business. It must be examined concerning the nature of the task and the environment; for example, if the work is in a fast-changing environment, it may not be suitable to authorise work under the same permit the next day since new dangers may need a modification in the permit conditions.

- The precise work site; where the work is performed can have a significant impact on the dangers involved with a job.

- A complete description of the work is required to demonstrate that all aspects of the job and potential dangers have been considered, as well as to ensure that individuals conducting the work understand the scope of the permit. It should allow for challenges, inspections, and audits by coworkers or an outside auditor.

- The potential hazards and dangers, as well as the likely results if the risk occurs. Frequently confirming that RAMS have been received and examined.

To see our full list, click here.

Understanding the Core Elements of a Permit to Work System

In the world of workplace safety, a Permit to Work (PTW) system is a critical component for managing high-risk activities. It’s not just a formality; it’s a detailed process designed to ensure safety and compliance at every step. Let’s delve deeper into the key elements that make up an effective PTW system:

- Hazard Identification: The first step in any PTW system is to identify potential hazards associated with the work. This could range from physical dangers like machinery, to environmental factors like extreme temperatures. It’s about understanding what could go wrong before it does.

- Risk Assessment: After identifying the hazards, the next crucial step is assessing the associated risks. This involves evaluating how likely it is that a hazard could cause harm and the potential severity of that harm. It’s a process of quantifying dangers to prioritise control measures effectively.

- Implementing Control Measures: Once the risks are assessed, it’s time to put in place measures to either eliminate or mitigate these risks. This could include engineering controls like safety barriers, administrative controls like work procedures, or even personal protective equipment (PPE). The key is to tailor these controls to the specific hazards and risks identified.

- Issuing and Approval of Permits: A PTW isn’t just a piece of paper; it’s a formal agreement that the identified risks are being managed. It involves a thorough review by competent personnel who can assess the adequacy of the control measures. Only once this approval is given can the permit be issued and the work begins.

- Continuous Monitoring and Review: A PTW system is dynamic, not static. It requires ongoing monitoring to ensure that the control measures remain effective throughout the duration of the work. Any changes in the work environment or scope must lead to a reevaluation of the permit.

Incorporating these elements into your PTW system is not just about regulatory compliance; it’s about creating a safer, more aware, and responsible workplace. By rigorously identifying, assessing, and controlling risks, and ensuring continuous monitoring, a PTW system becomes an invaluable tool in the quest for a zero-incident workplace.

Common Types of Permits Used in Permit-to-Work Systems

Permit to Work (PTW) systems are essential for managing high-risk tasks and ensuring safety in various industries. Different types of permits are used based on the nature of the job, each addressing specific hazards and safety protocols. Here are some common types of permits used in PTW systems:

1. Hot Work Permit

Hot Work Permits are used to authorise tasks that involve heat, sparks, or open flames, such as welding, soldering, or flame cutting. These permits ensure that appropriate safety measures, like fire watches and equipment inspections, are in place to prevent fires and explosions

2. Cold Work Permit

Cold Work Permits cover tasks that do not produce sufficient heat to ignite flammable materials but can still be hazardous. Examples include working with solvents, resins, or corrosive materials, and performing tasks that involve heavy physical labour or machinery operation

3. Confined Space Permit

Confined Space Permits are required for work in spaces with limited entry and exit points, such as tanks, vessels, silos, or trenches. These permits ensure that hazards like asphyxiation, toxic atmospheres, and engulfment are identified and mitigated. Safety measures include proper ventilation, gas monitoring, and emergency rescue plans

4. Electrical Work Permit

Electrical Work Permits are necessary for tasks involving contact with energised electrical conductors. These permits are essential for maintaining safety during electrical installations, maintenance, or repairs, and they outline specific safety protocols to prevent electrical shocks and other hazards

5. Ground Disturbance Permit

Ground Disturbance Permits are used for excavation and trenching activities. They help ensure the safety of workers and the surrounding environment by identifying risks such as soil collapse, striking underground utilities, and exposure to hazardous substances. Proper planning, including marking entry and exit points and using protective systems, is crucial for these tasks

6. Breaking Containment Permit

Breaking Containment Permits are essential for tasks that involve the potential release of hazardous gases or liquids. These permits are commonly used in the oil and gas industry to ensure that safety measures are in place to prevent spills, leaks, and other dangerous incidents. They include protocols for safe handling and containment procedures

7. Chemical Work Permit

Chemical Work Permits are required for activities involving hazardous chemicals, such as handling, mixing, or disposing of toxic or corrosive substances. These permits ensure that workers are aware of the risks and follow safety protocols, including using personal protective equipment (PPE) and proper handling procedures

8. Working at Height Permit

Height Work Permits are used for tasks performed at elevated locations, such as on ladders, scaffolds, or rooftops. These permits ensure that appropriate fall protection measures, such as harnesses and guardrails, are in place to prevent falls and related injuries

Incorporating these various permits into your PTW system helps manage specific hazards associated with different tasks, ensuring a comprehensive approach to workplace safety. By understanding and implementing the correct permits, organisations can significantly reduce the risk of accidents and incidents, promoting a safer working environment.

Navigating Challenges and Implementing Solutions in PTW Systems

Implementing a Permit to Work (PTW) system can be a complex task, fraught with challenges that need careful navigation. However, with every challenge comes a solution, and understanding these can vastly improve the efficacy of your PTW system. Here’s a look at some common hurdles and practical ways to overcome them:

Balancing Safety and Efficiency: One of the biggest challenges in implementing a PTW system is ensuring that safety measures do not impede operational efficiency. The solution lies in creating a PTW process that is both thorough and streamlined. This can be achieved by adopting digital solutions for quicker permit approvals and ensuring that safety protocols are clear and easy to follow, thus reducing downtime without compromising on safety.

Ensuring Comprehensive Understanding and Adherence: It’s essential that all employees, not just the safety team, understand the importance of the PTW system. To achieve this, regular training and clear communication are key. Interactive training sessions, clear and concise documentation, and regular safety meetings can help in reinforcing the importance of adhering to the PTW system.

Dealing with Resistance to Change: Introducing a new system often meets with resistance. To manage this, involve employees in the development and implementation of the PTW system. This inclusion fosters a sense of ownership and understanding among the staff, leading to better acceptance and adherence.

Maintaining Up-to-Date Procedures: The work environment is constantly changing, and your PTW system needs to keep pace. Regular reviews and updates of the PTW procedures ensure that they remain relevant and effective in addressing new hazards and work methods.

Integration with Other Safety Systems: A PTW system shouldn’t operate in isolation. Integrating it with other safety and operational systems within your organisation can enhance overall safety management. This holistic approach ensures that all safety aspects are covered, providing a more robust safety net for your operations.

By addressing these challenges with well-thought-out solutions, your PTW system can become a cornerstone of your workplace safety culture. Remember, a successful PTW system is one that not only ensures compliance but also promotes a safe and efficient working environment.

Aligning PTW Systems with Regulatory and Compliance Standards

In the realm of health and safety, compliance with regulatory standards is not just about legal adherence; it’s a commitment to the well-being of your workforce. A well-structured Permit to Work (PTW) system is instrumental in aligning workplace practices with these essential standards. Let’s explore how PTW systems interface with regulatory and compliance aspects:

Adhering to Health and Safety Executive (HSE) Guidelines: In the UK, the HSE provides comprehensive guidelines for workplace safety. A robust PTW system ensures that your organisation meets these guidelines, especially in managing high-risk activities. By following HSE’s best practices, you can demonstrate due diligence in risk management and safety procedures.

Complying with Occupational Safety and Health Administration (OSHA) Standards: In the United States, OSHA sets forth standards to ensure workplace safety. A PTW system helps in complying with these standards, particularly in controlling hazardous energy (lockout/tagout procedures) and managing tasks in confined spaces or at heights.

Meeting International Standards like ISO 45001: This global standard provides a framework for occupational health and safety management systems. Implementing a PTW system that aligns with ISO 45001 can help in establishing a globally recognized approach to managing occupational health and safety risks.

Integrating with European Union Regulations: For businesses operating within the EU, aligning with directives such as the Seveso III Directive, which deals with the control of major-accident hazards involving dangerous substances, is crucial. A PTW system tailored to these regulations ensures compliance and enhances safety management.

Ensuring Consistency with Industry-Specific Guidelines: Various industries have specific safety guidelines, like the HSG 250 for the petroleum, chemical, and allied industries. A PTW system should be customised to adhere to these industry-specific regulations, ensuring comprehensive coverage of all safety aspects pertinent to your field.

Incorporating these regulatory and compliance aspects into your PTW system not only ensures legal compliance but also reinforces your organisation’s commitment to maintaining a safe and responsible work environment. It’s about going beyond mere compliance; it’s about setting a standard for safety and excellence in your industry.

What Resources are Available to Assist with the Permit to Work Process?

Numerous organisations still use triplicate permits to work pads to manually manage this process. While there is no wrong way to manage this process as long as it is strong, this manual technique is prone to errors, missing information, and inconsistencies in how permits are completed. With the rise of automation and electronic permits, many businesses have shifted away from paper-based systems, and toward digital solutions.

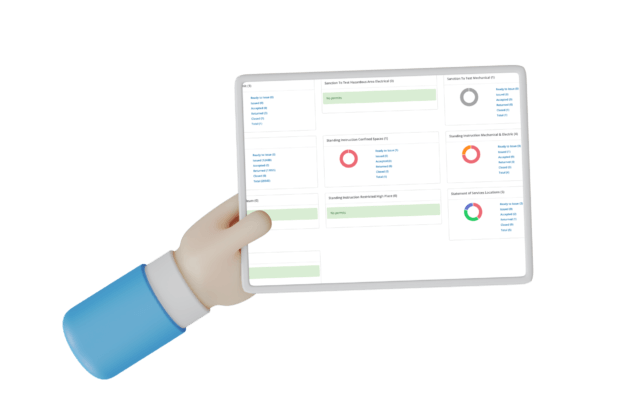

Verature is a contractor management system that offers a streamlined procedure for managing the hired contractor lifecycle, from project booking to document control, remote inductions and assessments, access control, and permit checks and audits, as well as permit search, filter, and export.

We also include permit mapping capabilities, which digitally plot where permits are given, mimicking the site map on the noticeboard that we’re all familiar with. Verature delivers a robust, trackable, and auditable permit-to-work system to private and public sector clients across a variety of different industries, with built-in workflow and logic and a filterable and exportable database of issued permits.

Success Stories: How Verature Transforms Permit to Work Systems

Falmouth Exeter Plus

“Verature is a great system that is very intuitive, dynamic, and user-friendly. The system’s reporting capability provides increased visibility and control of all contractor visits across our multiple sites, ensuring contractors are working safely, with all work and visits approved and recorded.”

Ornua

“We could initially see the value in the Verature system and knew it would be the solution to our problems and that we needed to implement it immediately; we even spoke to other users and had a site visit to personally see the positive impact it had on other businesses.”

University of Strathclyde Glasgow

“My team have been very impressed with the level of support and professionalism shown by the development team at Verature. The Verature system is enabling us to finally gain the visibility and control we needed to implement to move forward with our contractor management processes.”

Goodwood

“The Verature system is enabling us to work collaboratively with our contractors and ensure compliance standards. We’ve found the Verature Team very easy to work with, the coding is excellent and the system itself is self-explanatory; it is working exactly how we envisaged for this first phase, and we can’t wait to roll it out around the Estate.”

Sibelco

“The Verature system has been really well received at Sibelco; it’s clean and user friendly. We now have a complete overview of our visitors and contractors on each of our sites to ensure they’ve completed the required inductions. The system is making it easy to ensure we are remaining accountable for the safety of our contractors when on site.”

These case studies highlight how Verature’s Permit to Work system enhances safety, compliance, and operational efficiency across various industries. By leveraging Verature, organisations can ensure that all contractor activities are monitored, approved, and recorded, significantly reducing risks and improving overall safety standards.

Features of Veratures Contractor Management System

Digital Permits

With Verature you can replicate your paper permits in digital format, including digital signatures, checks and approvals. Any permit types or required workflow can be replicated.

Permit Audit and Check

Perform on-site audits, attach documents and snap and attach images from any mobile or portable device.

Permissions and Workflows

Verature’s permissions and workflows ensure that only competent Users in the organisation can issue particular permit types. Built-in logic and mandatory fields prevent cutting corners and uncertainty that processes are being followed, ensuring no stage of the permit-to-work process has been skipped.

Permit Mapping Functionality

Permits issued will be plotted on your site map or a google map, helping to identify potential clashes in high-risk works.

Permits and Passes Reporting

Track the issue and return of permits. Reporting and querying functions enable you to filter and export all historically issued permits by location, date issued, permit type, permit status (returned incomplete, returned complete, not returned etc.), permit issuer etc. An audit activity log details who did what on a permit along each stage, with date, time and user stamps providing much-needed traceability.

Why is a Strong Permit to Work System Necessary?

Failure to manage high-risk work frequently results in the occurrence of an accident or dangerous incident. Because of the nature of the task, there is a considerable risk to life and property. Individuals or businesses held liable for failing to plan, adequately instruct, or estimate the hazards associated with the job may be penalised and punished for negligence.

Along with the personal and corporate danger of prosecution, an organisation’s reputation suffers when it fails to meet its commitments and acts without due diligence.

Overall, a permit-to-work system is a crucial tool for guaranteeing worker safety and equipment integrity. It helps to reduce the risk of accidents and incidents by formalising the work process and ensuring that work is done in a controlled and ordered manner.Book a demo now with a member of our team to find out more.

Stay up to date with all of our services by following us on Instagram!Book a demoFind out if you’re ready with our Verature Onboarding Kit

Not sure if Verature is right for you? We understand it’s not easy to make a decision on a new system, but that’s why we’ve created our Onboarding Kit to make that that process simple.

Check our package details

Find out no matter what package you choose, you’ll be getting the best features you need for you and your team so you can have continuous contractor compliance.

Make it your own

You’ll get to see and choose your customisation options, and check out the available add-ons and extras so the system is exactly what you want and need.

Quickly getting you started.

Keeping this guide with you, and working closely with us, we can walk you through each step so you can be completely up and running with your own Verature system.

More reasons to use Verature

It’s easy to get started.

Step 1

Book a demo of Verature with the team.

Step 2

We’ll chat through your requirements and see if Verature is right for you.

Step 3

We’ll send you demo access and our onboarding kit to help you decide what you need.

Step 4

You decide if we’re right for you. No pushy sales calls.

Step 5

Like what you see and hear? Let’s get you onboarded with Verature!